Aims: Start getting everything together for the literature report and the main report also, do the porous design in the stem

This week I’ve been working in my report and also looking how I will do the porous on the stem because their are a range of shapes that I will be using in order to analysis the stem I created. The shapes I will be using are; hexagonal, triangles and squares. These are going to be mounted in the stem and cut through in order to see the effects that it has on the stem and then compare it to other work which have been created already.

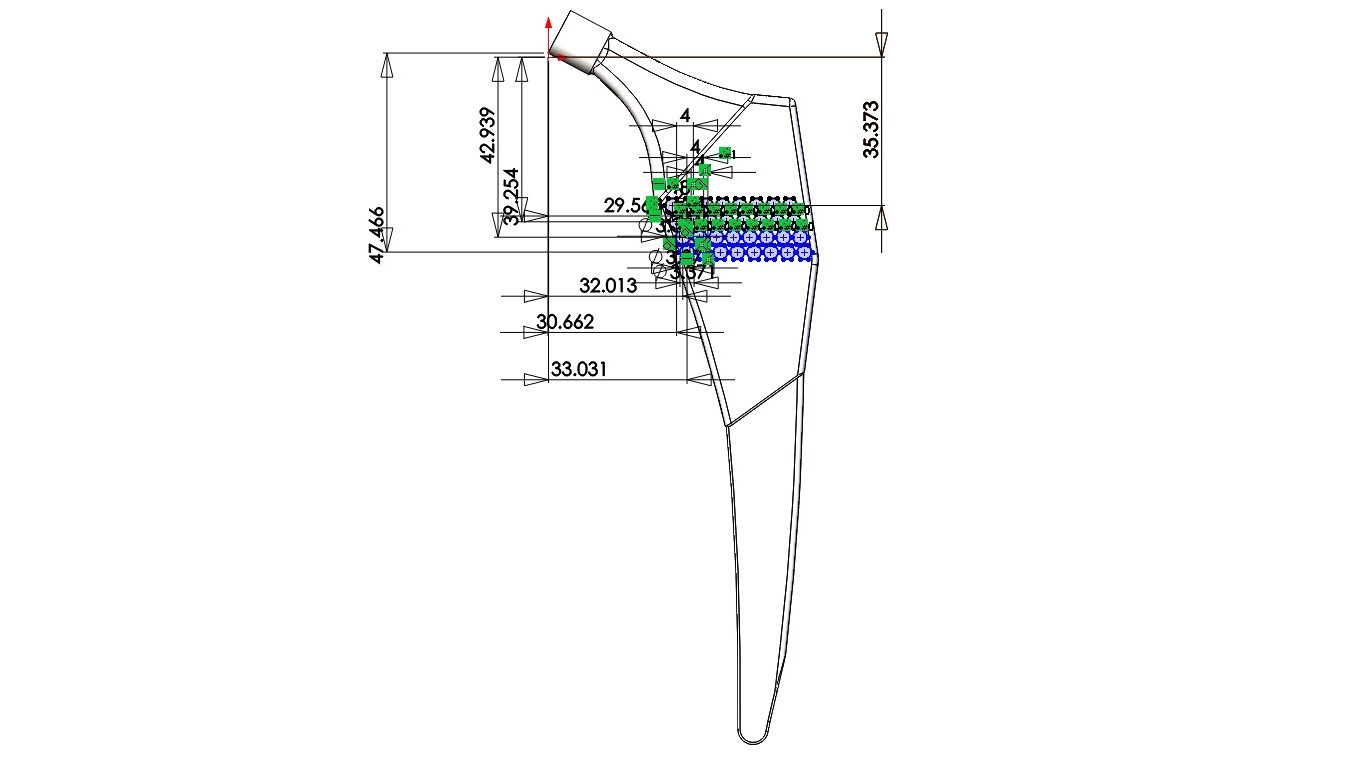

In Fig 1 you can see the way I started to design the porous structure, this is only using the hexagonal shape which I mentioned above. This was created in CAD but I encountered some difficulties due to the shape of the stem the shapes don’t seem to alien throughout the section which they need to go. When thinking about the FE am able to mesh it but it gets an error which for some reason the meshing don’t seem to finish in order to give me the simulation test which would be the next step after completing this part.

In Fig 2 is something that my stem would have to look like but they way other people have done it is by a coated layer which goes on top of the stem. In terms of shapes this one does not use any in particular.

In fig 3 there are some different images of how the porous structure have been designed using the same method as the one am doing. We notice that at the end of the image there is some sort of porous mesh which uses some sort of shapes. The shapes is not really clear but again they haven’t done the design onto the stem but as a coated layer which goes on top of the stem. My aim is to test the porous design onto the stem the effect would be different.

My new porous design is as shown in fig 3. I had to change the design because I found out that the lines between from the stem and the shape was thin and needed to be bigger, also the way it was laid out was wrong and I will encounter some problems in the FEA. The layout that I want to achieve is like a honeycomb design, with a spacing of 10mm in between and cutting it right through the stem. I will also be doing other shapes to see which one would be the best used.